Our group is engaged in technological research in order to respond to environmental issues and to build better homes that adapt to the climate, natural features, lifestyle, laws, etc. of each country as we expand Overseas.

IG Perfect Eco House

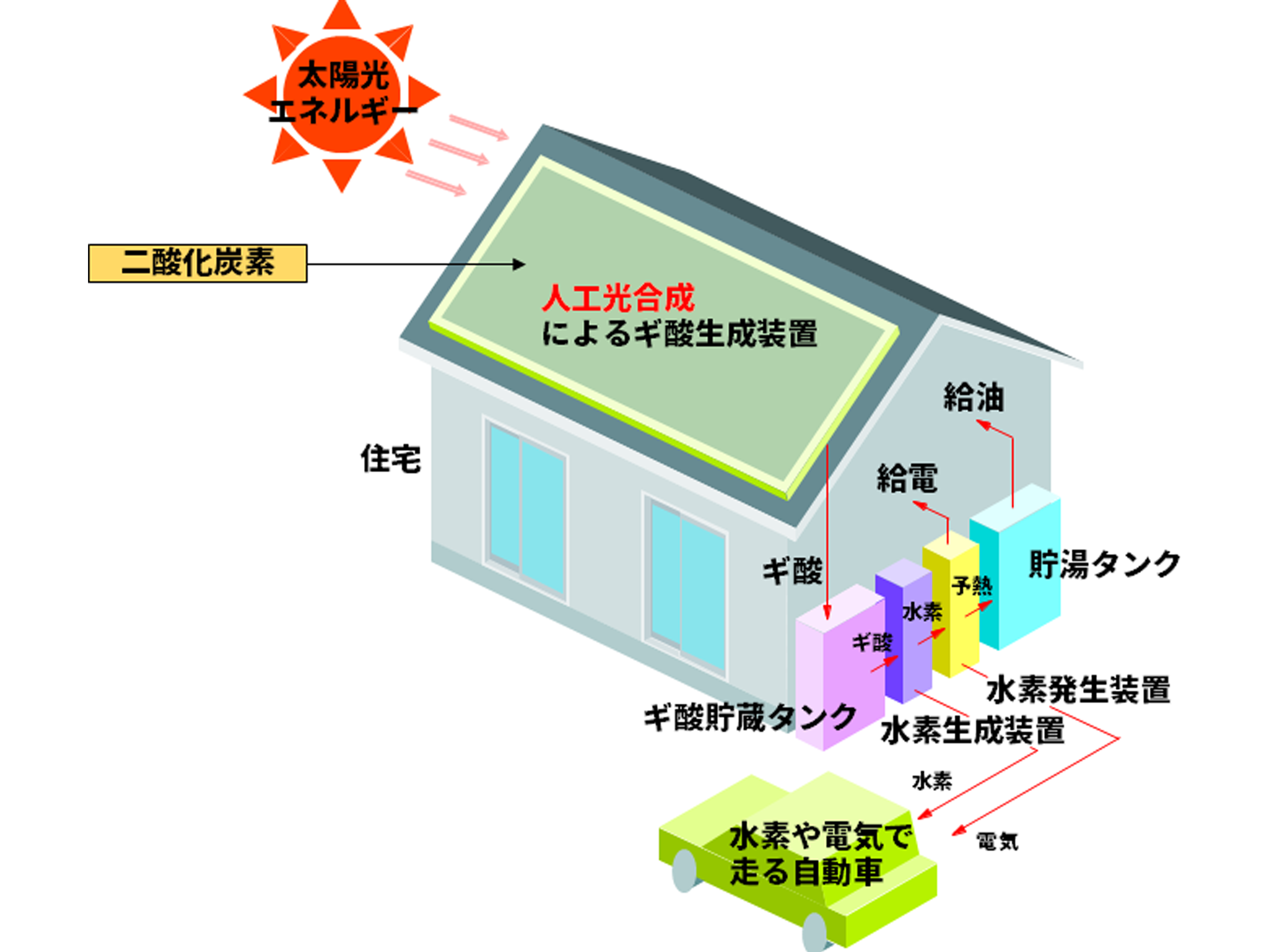

In collaboration with Osaka City University, we will begin demonstration experiments on the IG Perfect Eco House, an experimental building equipped with unprecedented artificial photosynthesis technology.

Once the IG Perfect Eco House technology is perfected, it will be possible to create a home that is self-sufficient in energy and uses carbon dioxide, and will be at the forefront of the housing industry.

Artificial photosynthesis

There is a need to solve the serious problem of global environmental pollution caused by greenhouse gases, and reduction targets have been set on a global scale, especially for carbon dioxide. If we as humans can develop a technology to create useful substances from carbon dioxide, similar to the photosynthesis that plants perform, it will become possible to reduce carbon dioxide emissions and create energy using carbon dioxide.

We believe that if we can develop technology that can cover all of a household's power consumption, we will be able to create future homes that are extremely environmentally friendly.

We aim to perfect "artificial photosynthesis technology" and contribute to a hydrogen energy society with low environmental impact.

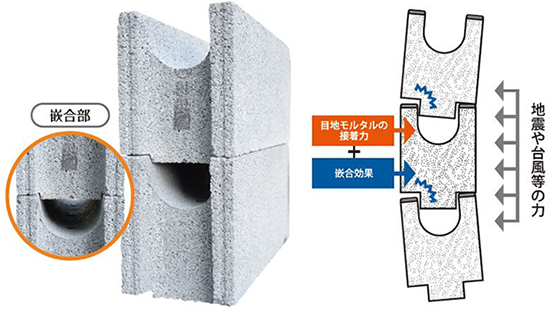

IG Strong CB method

We developed a construction method using CB (concrete blocks) to develop our housing business in hot and humid regions such as Southeast Asia.

CB is resistant to high temperatures and humidity, and is easy to manufacture and inexpensive, making it widely used in Southeast Asia.

However, the conventional CB construction method requires skilled technology to ensure a certain level of quality, and is vulnerable to shaking without reinforcing steel, which can lead to increased damage in areas where earthquakes and typhoons occur frequently. It was the cause.

Therefore, in order to solve these issues, we have developed and adopted the following three points.

As a result, compared to a general CB wall that does not fit, the structural strength against forces in the out-of-plane direction of the wall is approximately three times higher, and in full-scale vibration experiments (*2), the IG Strong construction method was We have confirmed earthquake resistance and safety. In addition, we have made the construction easier so that even non-skilled engineers can ensure high quality.

- *1 Patented in Japan and the United States, patents pending in 7 other countries

- *2 Conducted on August 8th and 9th, 2017 at the Vibration Experiment Facility of the Public Works Research Institute (Tsukuba City, Ibaraki Prefecture). Earthquake motions with a measured seismic intensity of 6 to 7 were continuously input to the test building, resulting in a shaking table response approximately 1.2 times that of the “Kumamoto Earthquake (Mashiki Town observation waves)” (within the performance range of the shaking table). implementation).

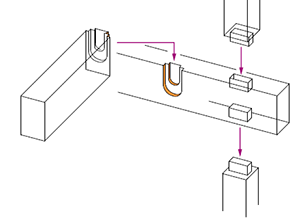

IDS method

We have developed our original 2 x 4 construction method.

The 2 x 4 construction method is a construction method that uses wood with a cross-sectional size of 2 inches x 4 inches, which is a common standard worldwide. Globally, this construction method is popular because it only requires cutting the material in the length direction, but there are many on-site construction steps for walls and floors, and it takes time to assemble. On Overseas other hand, while the wooden frame construction method that is mainstream in Japan allows assembly in a short period of time, it requires processing the joints between columns and beams and beams so that they "penetrate" and "interlock". The problem was that it was difficult to procure.

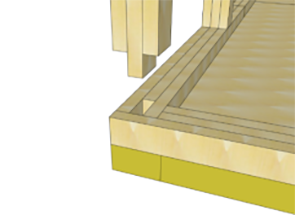

The IDS construction method developed by our company uses standard 2x4 lumber, which is easy to procure Overseas, and while it involves simple processing that only requires cutting to length, by stacking the lumber it is possible to create a shape that "fits" and "interlocks" like wooden frame construction, making it possible to assemble in a short period of time.

As for earthquake resistance, full-scale vibration tests (*1) were conducted, and there was no damage to the structural frame, demonstrating the earthquake resistance and safety.

Using this construction method, we built a model house in Vladivostok.

- *1 As a result of inputting seismic waves within the performance range of domestic vibration test benches, “seismic waves from the Tohoku Pacific Coast Earthquake (Kurihara City Tsukidate observed waves)” and “seismic waves 1.4 times as strong as the Kumamoto Earthquake (Mashiki Town observed waves)” were obtained from the shaking table. Measured above.